The researchers of the ELKH Centre for Energy Research (ELKH CER) have won an EU H2020 project proposal outstanding in terms of promoting innovation in Hungary. The CER staff of the Neutron Spectroscopy Department received the nearly 350 k€ project grant three-year for the development and introduction of a new industrial non-destructive materials testing standard. The EASI-STRESS project involves four major European research infrastructures (RIs), one university, two technology transfer companies and seven top industrial enterprises as partners. Four of the latter also have significant domestic industry implications. Subsidiaries of well-known companies such as Airbus, Rolls-Royce and Siemens, as well as EDF (a French nuclear power plant manufacturer), NEMAK (a foundry giant with an automotive supplier factory in Győr, for example) and the world’s largest steel producer (Acelor-Mittal) and 3D metal-printing company (Volum-E) are involved in the work.

The aim of the project is non-destructive X-ray and neutron diffraction analysis of internal residual stresses in materials/components; strengthening the dissemination of the measurement method and tools as well as developing new standards in close cooperation with industry. This technique allows a better understanding of the formation of internal residual stresses during the manufacture of various devices and predicting the in-use variation of stresses, thus the possible life-time and reliability of the products. In this way, comparing and incorporating directly the measured data into existing industrial design and modelling tools, will enable us to arrive fabricating better products. With the industry level of introduction of this method, manufacturers can, on the one hand, detect defects in the production of components, such as, for example, the formation of cracks due to poor welds or bending at wrong speed and temperature. On the other hand, as a quality assurance procedure, materials fatigue due to environmental influences during the use of objects, and thus service life-time, can be featured.

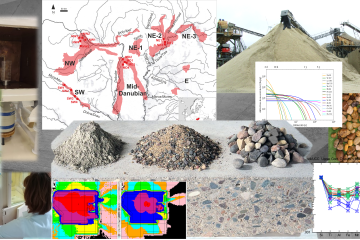

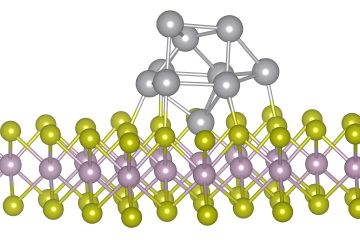

The essence of the method is the following: the parameters of the manufacturing processes greatly influence the material structure, e.g. in castings, the rate of solidification affects the position of the atoms in the alloy materials, and if the ideal crystal structure is not formed, an ‘internal stress remains’ within the material. By X-ray diffraction on the surface of the components, while with neutrons in the bulk of the materials we can ‘see’ the atomic level microstructure and from the diffraction patterns the internal stress value and distribution can be calculated.

In the modern production of machine parts, heat treatment and shaping by mechanical deformation are often used simultaneously. For example, in the case of multicomponent alloys, the metallurgical or phase composition in the object, including the residual stresses, depends on the processes used. In engineering design, large software packages have been developed to model such processes, the experimental validation of which is a prerequisite for the introduction of design results into production. Diffraction stress analysis is one of the most efficient non-destructive experimental methods, thus standardization of such measurement procedures would allow for industry-wide application. Incorporating this knowledge tool into the design process of metallic parts will result in reduced material consumption, more reliable and longer-lasting products, which also means significant environment and cost savings.

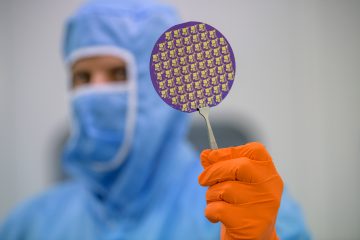

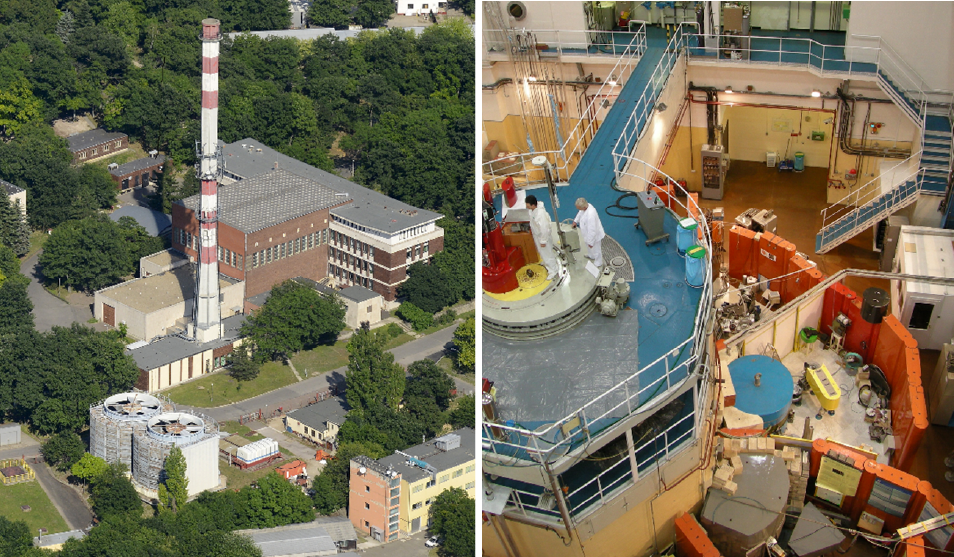

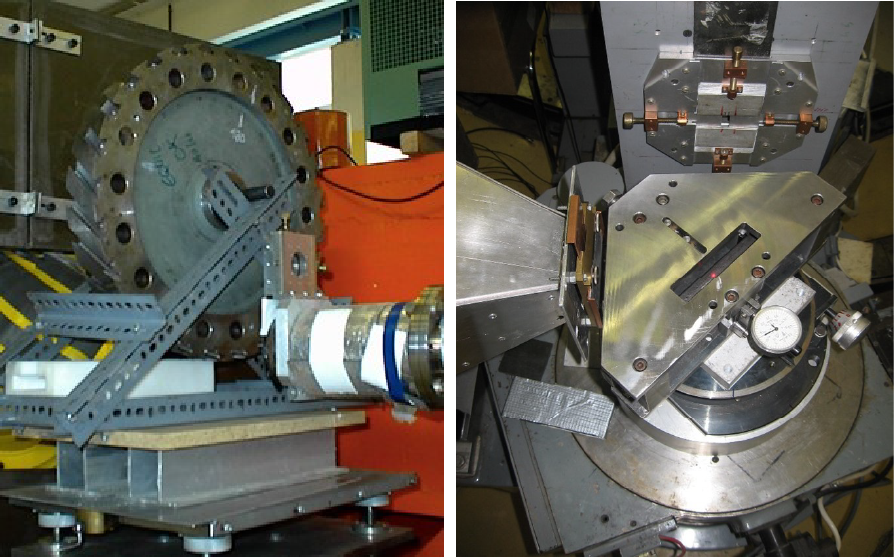

In the project, the industrial companies will define and produce test samples according to their profile, and also providing real components for the experiments. Diffraction measurements are to be performed by RIs: X-ray examinations at the two largest European synchrotron sources (ESRF-Grenoble, HZG-Hamburg), neutron experiments at the world’s largest neutron research facility (ILL-Grenoble) and at the Budapest Neutron Centre (BNC) as the largest domestic research infrastructure, a unit of the ELKH-CER. The University of Manchester, as well as the Danish and French tech-transfer companies (DTI, CETIM), ensure the coordination of modelling and validation; as well as they will take care of introducing the procedure as a European standard.