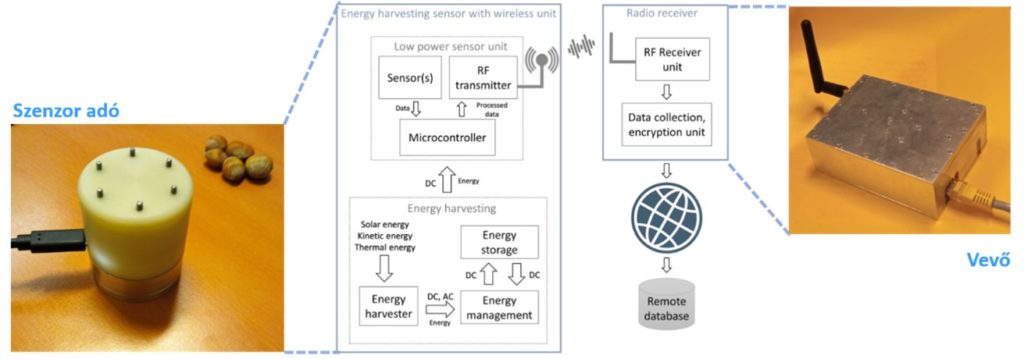

The Institute of Technical Physics and Materials Sciences of the ELKH Centre for Energy Research (EK MFA), along with BHE Bonn Hungary Electronics Ltd., have developed battery and wireless sensor networks which can be deployed in extreme environments. The sensor nodes scavenge energy from thermal and mechanical vibration sources from the ambient environment and communicate via a newly developed wireless RF protocol. These networks can be used in various real-life applications for health monitoring of civil infrastructures, real-time monitoring of bicycle traffic and vehicle control systems.

In continuously growing numbers, sensors are providing information in various fields of life, such as smart factories, transportation infrastructures, and agriculture. These devices often have to be positioned in hard-to-reach places where the wiring of the sensor or, in the case of a wireless sensor, battery replacement is either not feasible or expensive. In those cases, energy harvesting provides a viable solution. However, the exploitable sources are usually of a low level and their intensities fluctuate strongly depending on the time and place. The aim of the project was to develop smart autonomous systems which can adopt to the stochastic environment and are extremely power efficient.

The vibrational energy harvesters and sensor chips have been developed in the clean rooms of EK MFA, which has more than 20 years of experience in the field of micromechanical systems (MEMS) (www.nems.hu). The second stakeholder in the consortium, BHE Bonn Hungary Electronics Ltd., as a fully Hungarian-owned high-tech company, provided the required know-how to develop energy-efficient RF transmitters and sufficiently fast and sensitive receivers. Members conducted basic and applied research as well as proof-of-concept (PoC) developments for the project as described below.

The aim of the basic research was to investigate and realize a novel type of vibrational energy harvesters and frequency selective accelerometers with multiple electrodes. Conventional non-resonant accelerometers provide a uniform response in a broad frequency range; however, their sensitivity is often insufficient and they require a power supply. The researchers from EK MFA proposed a double-sided clamped Fermat spiral with a segmented top electrode. The operating principle of the device, fabricated in a 30-step standard semiconductor process, was verified by a frequency-swept electromagnetic shaker. In order to maximize the piezoelectric signals of the sensors, CMOS compatible nitride alloy layers, such as ScAlN, were also investigated as part of the project. By optimizing the technological conditions, ScAlN thin films showed a 5-times increase in the longitudinal piezoelectric coefficient compared to the conventional binary AlN (~6.0 pC/N) on a Si substrate. At similar deposition parameters, this value was found to be even higher for an Ni substrate (~10.0 pC/N), which bodes well for several applications where the high fracture strength is concerned.

Experts at BHE have developed two types of broad-range antenna (0.7-18 GHz) which are capable of extracting energy from conventional RF sources, such as GSM, UMTS, LTE, digital TV systems and even 5G networks.

Highlighted proof-of-concept systems:

Self-powered vibration diagnostic sensor (VibAn): The aim of the vibration diagnostics is the monitoring of the condition of various machines with rotating parts. These tests are usually performed on a one-off basis. However, there is an increasing demand for failure prevention by retrofitted real-time monitoring systems. The wireless sensor node developed by the project partners can detect vibrations in all x, y, and z directions in the frequency range of 10 Hz-2 kHz and has a low average power consumption (~1 mW). The energy harvesting function was demonstrated using both vibrational and thermoelectric generators. The sensor data recorded are sent via a novel, low-power RF protocol developed by the consortium members and their subcontractor (Ante Ltd., www.ante.hu/en/). The system consists of three units: i) a low-power transmitter circuit for the sensor node capable of sub-microsecond RF pulse generation at the ISM RF band of 2.4 GHz; ii) a receiver enabling the recording of time intervals with a resolution of 40 ns from up to 32 sensor nodes and the submission of each data point to the cloud via IP-based protocol; and iii) data acquisition and decoding software running on the remote server.

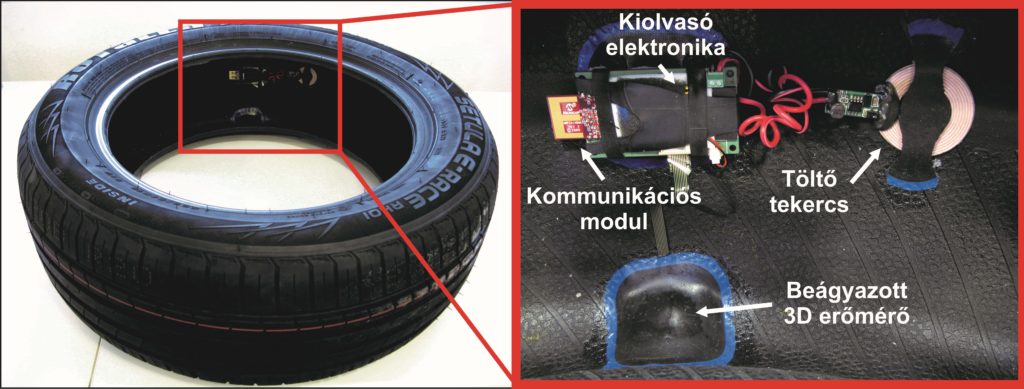

Integrated tire deformation sensor (TireForce)

Advanced vehicle control systems, especially self-driving vehicles, are gathering more and more information on the go to increase efficiency, reduce emissions, and increase safety. A set of sensors is now installed in the engine and placed in different locations of the car to monitor the vehicle’s movement and the environment. However, the interaction between the tire and road surface is not yet monitored. In the proposed concept, this is done through the tracking of tire deformation by a custom-developed 3D MEMS sensor mounted on the inner sidewall of the vehicle tire. The integrated tire sensor can provide valuable information on the surface condition of the road and predict tire slipping in advance. In cooperation with the Institute for Computer Science and Control (SzTAKI), the EK MFA team has carried out several dynamic tests on ZalaZone (https://zalazone.hu/) and kick-plate tracks. A neural network with three hidden layers and 114 neurons in total was used to teach the tire sensor with the assistance of the car’s (Nissan Leaf) on-board sensors. Following the learning process, the predicted output values showed excellent agreement with several dynamical parameters, such as yaw rate, and transverse/longitudinal accelerations, which proves its potential for use in next-generation vehicle control systems.

Bicycle traffic monitoring (LogLine): The portable sensor-line was developed at the request of traffic experts to record the number, the crossover position, the speed, the direction of travel, and wheelbase of passing bicycles. The recorded data are transmitted by a solar-cell powered data collector unit using the LoRaWAN narrow-band RF protocol. So far, almost 270,000 cyclists have been counted by the LogLine sensor all around Budapest (https://logline.hu/).

Further Information:

EK MFA Nanosensors Lab: http://www.nems.hu

BHE Bonn Hungary Electronics Ltd: http://www.bhe-mw.eu/

Contact:

János Volk, principal investigator, www.nems.hu

EK MFA, 1121 Budapest Konkoly Thege Miklós út 29-33.

volk@mfa.kfki.hu , +36 1 392 2222/3474