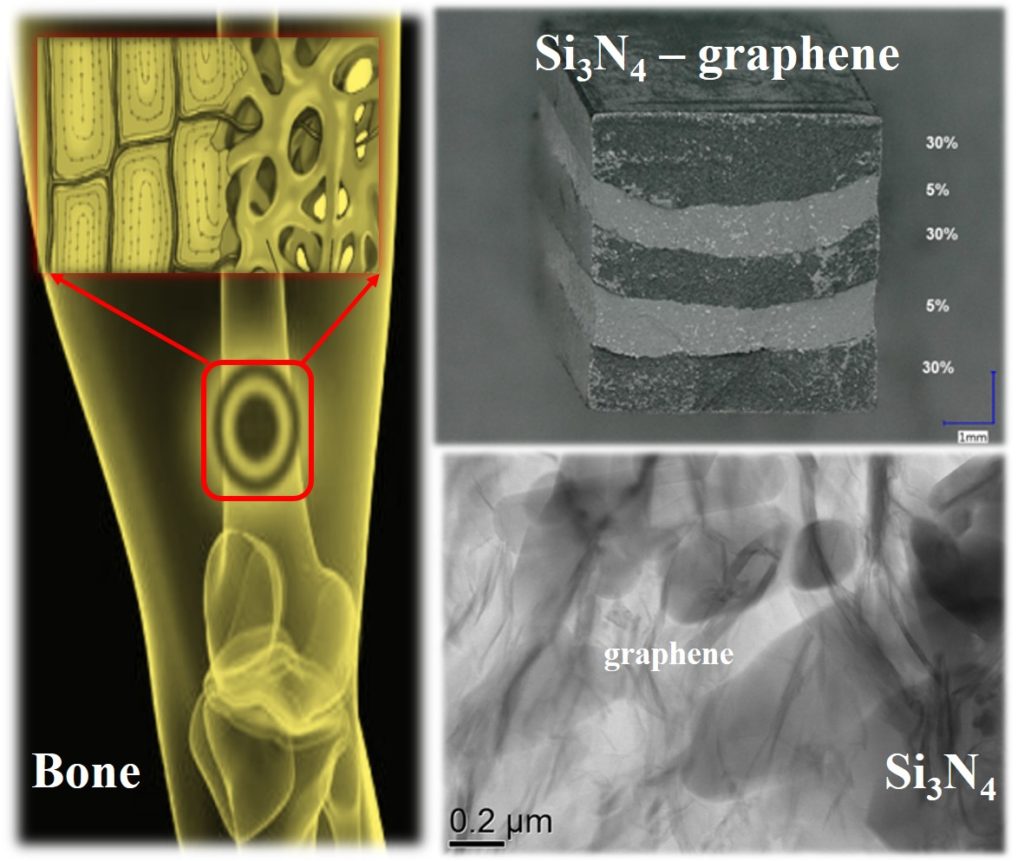

Researchers at the Institute of Technical Physics and Materials Science, Centre for Energy Research of the Eötvös Lóránd Research Network (EK MFA) the firstly produced the gradient-structured Si3N4 ceramics with few layers graphene by attritor milling and hot isostatic pressing. Development was a part of the “Graphene Flagship” FLAG-ERA Joint Transnational Call 2017 partnership for graphene innovation developments supported by the European Commission. The partners of consortium lead by Dr. Csaba Balázsi (EK MFA) are researchers from the Fraunhofer Institute of Ceramic Technology and Systems (Fraunhofer IKTS, Germany) and the Institute of Materials Science of the Slovak Academy of Sciences (IMR SAS, Slovakia).

Graphene Flagship Partnering Project „CERANEA” develops graphene-filled ceramic sandwiches that deliver materials with enhanced properties and functionalities.

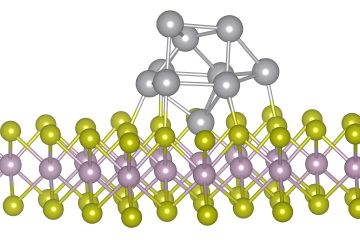

The mineralised structures of some bones, seashells and trees have something in common: their composition varies gradually throughout their volume, providing multiple functional roles at once. These are classified as functionally graded materials (FGMs) and can also be artificially engineered with tailored properties for numerous applications, including biomedical implants, optoelectronic devices, sensors and batteries.

Silicon nitride as an implant has a high novelty in orthopedic surgery. The ceramic-graphene sandwich structure developed by the researchers is very similar to human bone. The outer part is a Si3N4 bulk ceramic with the same mechanical properties as solid bone. With the addition of graphene, a porous Si3N4-graphene ceramic composite with open and closed porosities similar as the bone structure can be formed.

The porosity and conductivity of final composite can be influenced by graphene amount, which are also useful properties for other industrial applications.

Further information: